Background

A smart window uses electrochromic technology to switch between clear and tinted states on demand to block sunlight and solar heat while still providing an unobstructed view of the outdoors.

Each smart window is connected to a a network of window controller which is powered by a control panel:

Previous generation window controller

Project Objective

To lower the cost/sq ft of Smart Windows, I worked on making the controls cheaper. The new generation smart window controller aims to power four windows at once, requiring it to be designed from the ground up to enclose the new PCBA that generates more heat.

New smart window controller

Design

Material

The housing is made of AL 6061 for the prototyping and initial prodoction run due to its availability and machinability. As we shifted and enabled die casting for production, the final material was ADC 6. Both alloys were chosen also due to their high thermal conductivity to dissipate heat generated from the PCBA.

Heat Transfer Features

Fins were added to the top of the housing to act as a heat sink. Thermal interface bosses were also created to reduce the gap between the hot components on the PCBA and thermal pads are inserted in between to facilitate heat transfer. Chamfers were also added to the bosses to increase cross sectional area for conductive heat transfer.

EMI Shield

A custom designed stamped sheet metal was used as an EMI shield to contain the radio frequency from the PCBA to stay compliant with FCC commercial and residential regulations.

Seal

An Urethane based resin is dispensed to the bottom of the assembly to seal the opening once it cures.

Custom silicone gasket and plastic retainer were designed and made to seal the connectors

Manufacturing Fixture

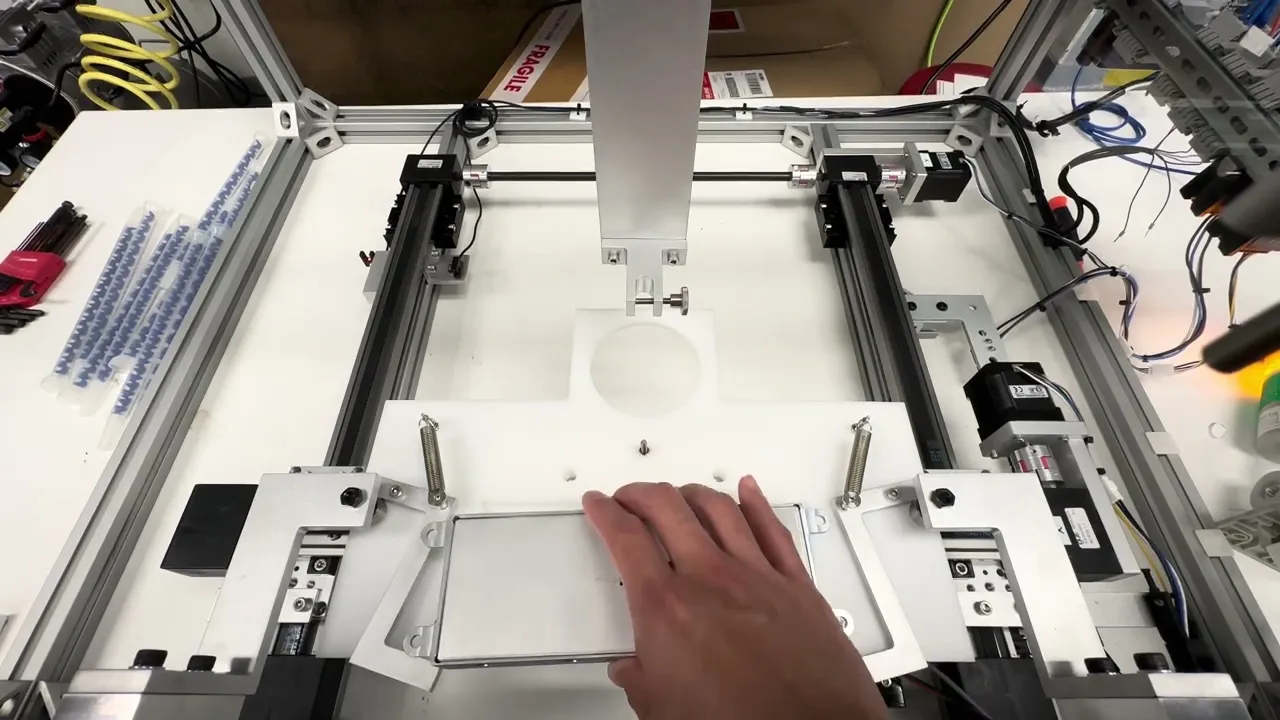

A custom manufacturing fixture was designed and fabricated to automate the resin dispensing process. It's a combination of a XY gantry with additional accessories connected to a resin dispenser:

A platform that is able to hold an assembled unit was installed to the XY gantry and I programmed it to move in an optimized path while having it synced with the dispense pressure and volume to ensure the resin covers the surface area and prevent material overflow/undershot

Here's the loading sequence of the potting fixture:

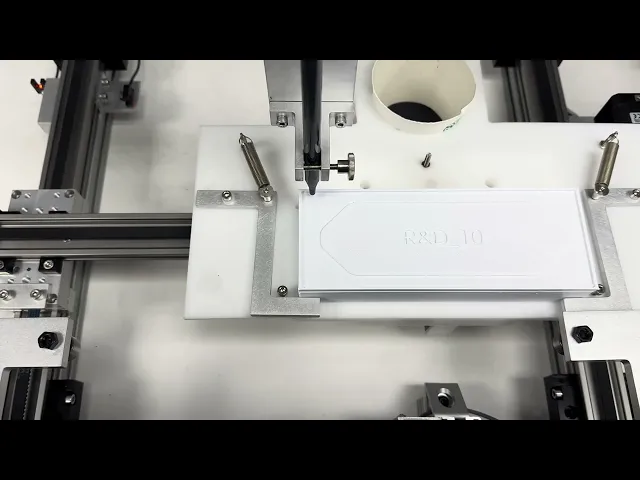

And here's the potting fixture dispensing resin on a prototype test assembly in action:

I tested a variety of patterns that was optimized for speed and potting material consumption and they were aligned with the resin dispenser's shot size and pressure. It was important that I accounted for lag when the XY gantry changes direction which will cause more potting material to be dispensed (eg. the corner sections):

Here are the electrical components which include Digital I/O, XY gantry controller etc. that make the assembly work:

Related Projects

Keyboard Tray Redesign

Jun 1, 2024

Powered Skid Steer Door

Jan 14, 2020

Os Acetabuli Fixation Medical Device

Jan 4, 2021

Laser Tower 3000

Dec 3, 2020

Fiber-Reinforced Polymer Research

Jan 7, 2020

SLS Surface Roughness Optimization Research

May 13, 2019